Coconut Shell Filler Slab Roof

After these tests compressive strength of bare dome shaped coconut shells was found to be 15 kn indicating that it can be used as filler materials thanks to its natural dome shape and its durable chemical constituents.

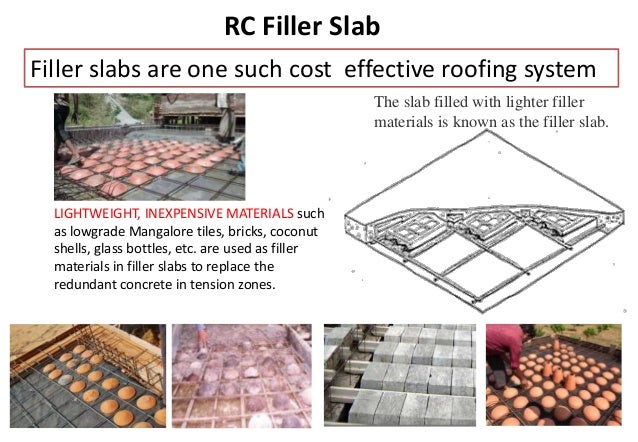

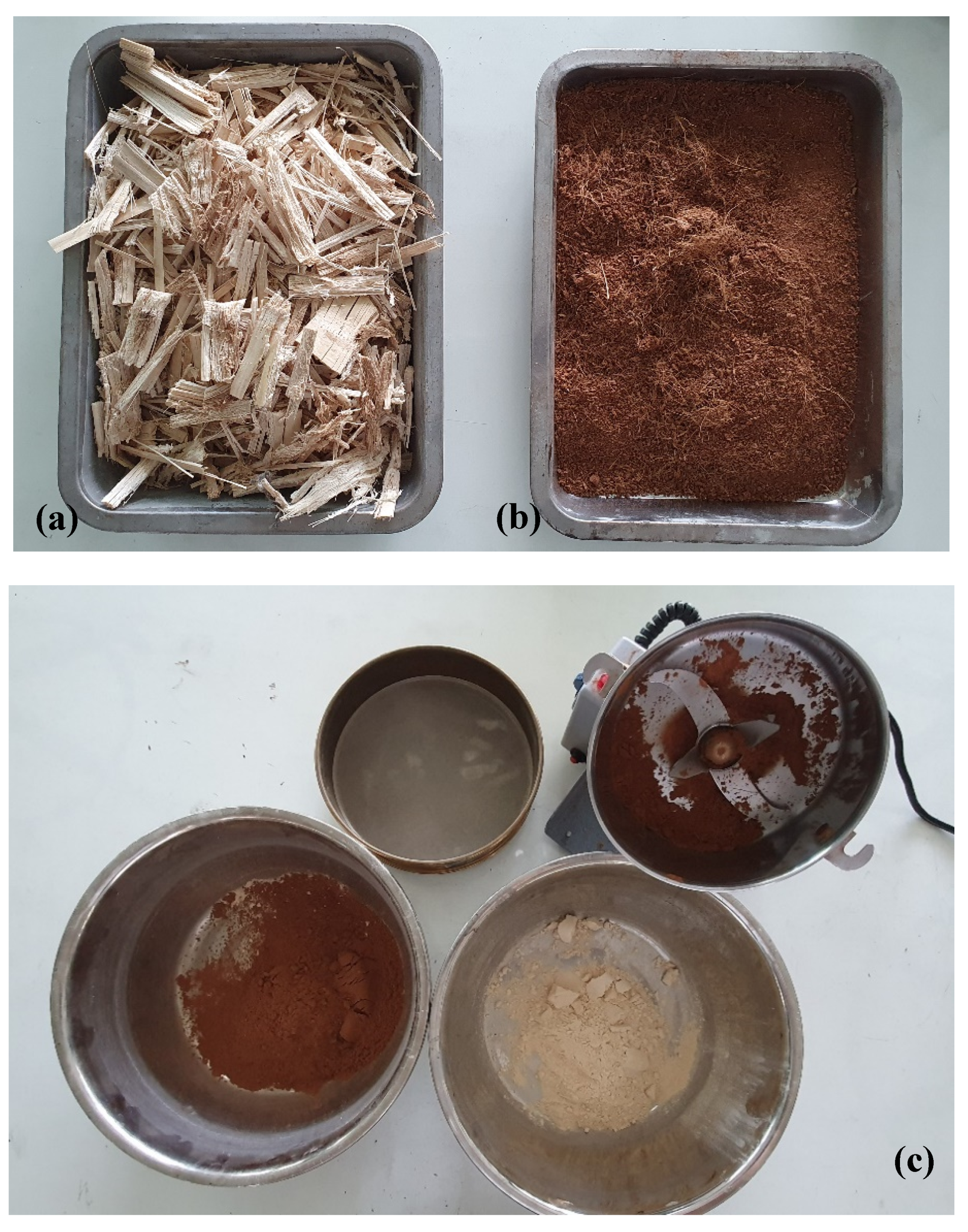

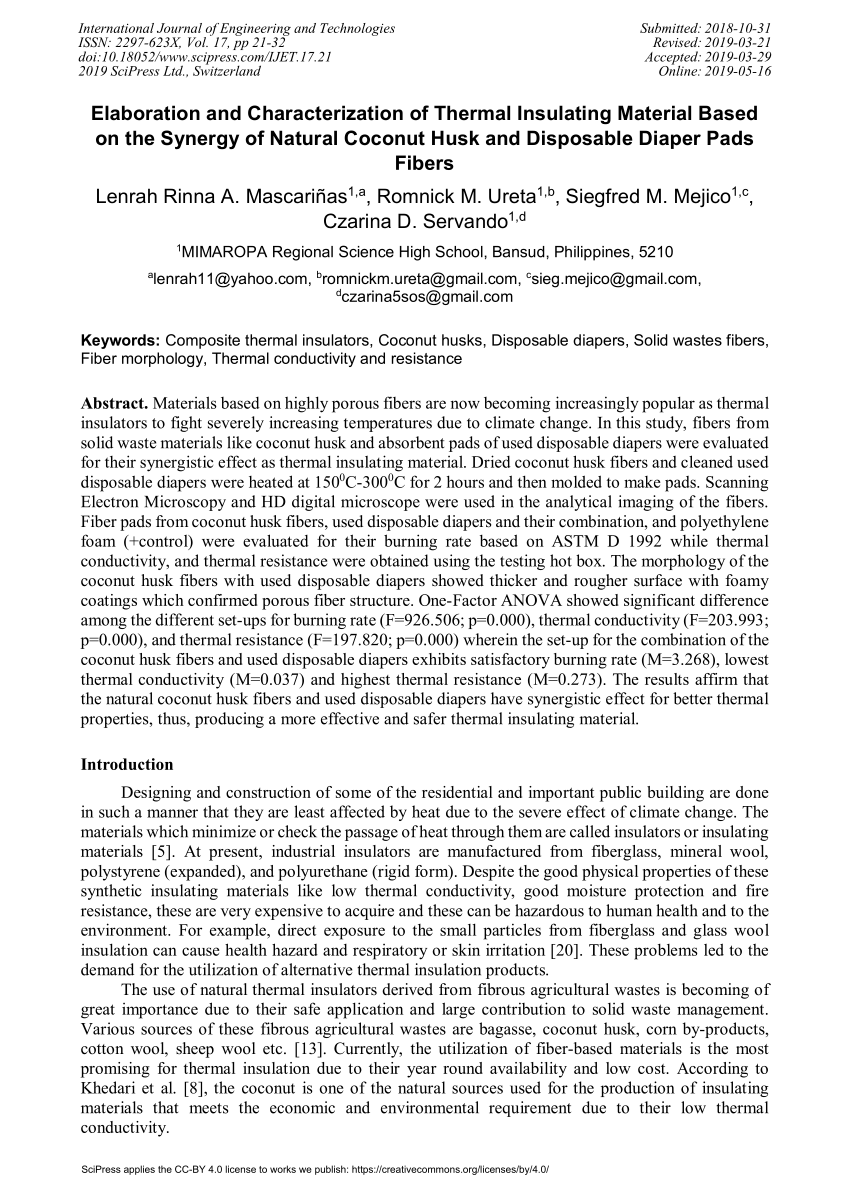

Coconut shell filler slab roof. Can be used as filler materials. Light weight inert and inexpensive materials such as low grade mangalore tiles burnt clay bricks hollow concrete blocks stabilized mud blocks hollow mud blocks clay pots coconut shells etc. These unnecessary concrete portions can be filled with some light weight materials and such slabs where concrete in tension zone is reduced by the use of light weight fillers are known as filler slabs. Common filler materials are light weight materials like mangalore tiles clay pans bricks waste bottles coconut shells thermocol etc.

Filler slab one way to make a boring and expensive concrete slab sexy lighter and cheaper is to use a filler slab. The impact resistance of coconut shell concrete is high when compared with conventional concrete. Though coconut shells mud bricks earthen pots thermocol etc can be used as filling materials clay roofing tiles are commonly used as fillers in slabs. Since filler roof tiles are firmly bonded to and covered by concrete it does not collapse under the impact of say a coconut falling on the roof.

Moreover its pleasing finished look can even be used for slabs to give aesthetic appearance. The coconut shell cement composite is compatible and no pre treatment is required. There is no reductoin in the structural strength of the slab at all and it will act as a normal load bearing slab. The good indicators of coconut shell quality as aggregate of concrete roof tiles are particles shape and texture resistance to crushing absorption and surface moisture and light weight.

A filler slab is where we replace a portion of concrete in the tension zone of the slab with inexpensive lightweight filler materials such as clay roof mangalore tiles bricks earthen pots coconut shells glass bottles or any other creative material you can think of. P mohammed zakiulla it was seen that conventional slab withstood 13 kn more load than the filler slab with coconut shells as filler material this is due to the presence of filler materials in the tension zone of filler slab 2017 study the filler slab as alternative construction technology amit d chougule manoj h. With proper supervision and workmanship leaks can be avoided. The chance of a leak in a filler slab is much the same as the conventional r c c slab.

Coconut shells filler slab roofs are basically solid reinforced concrete slabs with partial replacement of concrete by a filler material that is cheaper and lighter. Coconut shells are applicable as partial substitute as coarse aggregates for concrete roof tiles. Reduces the cost of the slab by around 25 30. These materials are laid in the grids of steel reinforcement rods and concreting concrete topping is done over them.